Introduction to Vacuum Circuit Breakers

At AIERWAY, the Vacuum circuit breaker is not just a product but a symbol of innovation, safety, and reliability in the electrical industry. A vacuum circuit breaker is a type of circuit breaker where the arc quenching takes place in a vacuum. It is widely used in medium-voltage power distribution systems because of its superior performance, long life, and minimal maintenance requirements. AIERWAY focuses on delivering high-quality vacuum circuit breakers that meet international standards and serve diverse industrial applications.

Understanding the Importance of Vacuum Circuit Breakers

The vacuum circuit breaker plays a crucial role in ensuring electrical safety and efficiency. It interrupts electrical currents and prevents damage caused by short circuits or overloads. The main advantage of a vacuum circuit breaker lies in its ability to extinguish the arc rapidly due to the absence of gas or oil. This results in reduced maintenance, compact design, and eco-friendly operation. AIERWAY’s vacuum circuit breaker units are designed for maximum performance and reliability even in the most demanding environments.

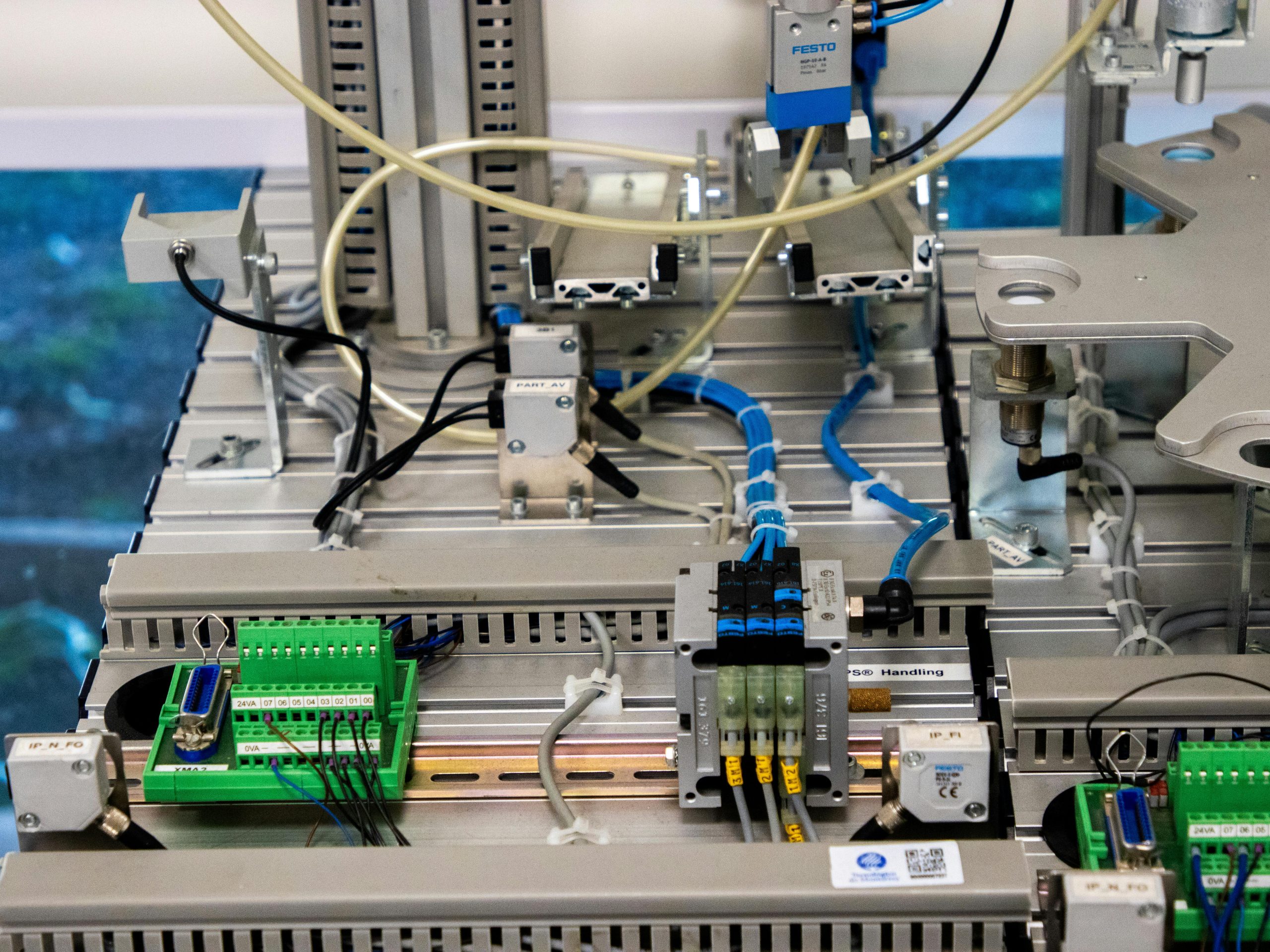

AIERWAY’s Advanced Production Facility

AIERWAY has established a world-class manufacturing facility equipped with the latest technology for vacuum circuit breaker production. The plant integrates precision engineering, automated processes, and strict quality control systems. Each vacuum circuit breaker is manufactured under close supervision, ensuring consistency and adherence to international standards. The facility also incorporates modern testing laboratories to guarantee that every vacuum circuit breaker leaving AIERWAY meets customer expectations.

Step 1: Material Selection and Preparation

The vacuum circuit breaker production process begins with the careful selection of high-grade materials. AIERWAY uses premium metals, ceramics, and insulating materials to ensure durability and performance. Every component used in the vacuum circuit breaker must withstand high voltage and mechanical stress. The raw materials undergo strict inspection before entering the production line, ensuring that each vacuum circuit breaker starts with a foundation of quality.

Step 2: Manufacturing of the Vacuum Interrupter

The vacuum interrupter is the heart of the vacuum circuit breaker. AIERWAY’s engineers manufacture this component with extreme precision. The interrupter’s contacts and housing are made in a clean and controlled environment. The vacuum is created inside the interrupter by advanced sealing technology. This step ensures that the vacuum circuit breaker can effectively interrupt electric arcs and operate safely over a long lifespan.

Step 3: Assembly of the Main Components

After the vacuum interrupter is completed, the next phase involves assembling it with other major components. The vacuum circuit breaker assembly includes operating mechanisms, insulating supports, and arc-extinguishing chambers. AIERWAY’s technicians follow strict assembly procedures to maintain accuracy. Each vacuum circuit breaker is assembled with the aid of precision machinery to ensure uniformity and minimize errors during the production process.

Step 4: Quality Testing and Inspection

Every vacuum circuit breaker manufactured by AIERWAY undergoes a comprehensive testing process. The tests include mechanical endurance, dielectric strength, temperature rise, and short-circuit performance. AIERWAY’s quality control department ensures that each vacuum circuit breaker complies with international safety and performance standards. Testing guarantees reliability and helps maintain the reputation of AIERWAY as a trusted vacuum circuit breaker manufacturer.

Step 5: Surface Treatment and Finishing

The vacuum circuit breaker parts are treated for corrosion resistance and surface durability. AIERWAY applies advanced coating and finishing processes to enhance the aesthetic and functional quality of each vacuum circuit breaker. Proper finishing ensures that the vacuum circuit breaker can withstand environmental factors and maintain long-term performance in various operating conditions.

Step 6: Final Assembly and Packaging

After all parts are tested and finished, AIERWAY performs the final assembly of the vacuum circuit breaker. The assembly is carried out by skilled technicians who ensure that every connection and mechanism functions smoothly. Once assembled, the vacuum circuit breaker undergoes a final inspection before being packaged. AIERWAY uses secure and eco-friendly packaging methods to protect the vacuum circuit breaker during transportation and delivery.

Step 7: Customer Support and After-Sales Service

AIERWAY’s commitment to excellence extends beyond manufacturing. The company provides complete after-sales support for every vacuum circuit breaker sold. This includes installation assistance, maintenance training, and technical guidance. AIERWAY ensures that every customer receives maximum value and performance from their vacuum circuit breaker investment.

Innovations in Vacuum Circuit Breaker Technology

AIERWAY continues to invest in research and development to enhance vacuum circuit breaker technology. The company is exploring digital monitoring systems, smart switching capabilities, and environmentally sustainable materials. These innovations help improve the efficiency, safety, and automation of vacuum circuit breaker systems. AIERWAY’s continuous improvement approach ensures that its vacuum circuit breakers remain at the forefront of modern electrical solutions.

Applications of AIERWAY Vacuum Circuit Breakers

AIERWAY’s vacuum circuit breaker products are widely used in power plants, substations, industrial plants, and commercial buildings. Their compact design, reliability, and high interrupting capacity make them ideal for medium-voltage networks. Each vacuum circuit breaker is designed to meet the specific needs of different industries, ensuring safe and stable power distribution.

Why Choose AIERWAY Vacuum Circuit Breakers

Choosing AIERWAY means choosing quality, innovation, and trust. The vacuum circuit breaker range from AIERWAY is built with advanced engineering, rigorous testing, and superior materials. Customers choose AIERWAY’s vacuum circuit breaker because of its long service life, low maintenance, and outstanding performance. The company’s dedication to excellence ensures that each vacuum circuit breaker delivers unmatched reliability in every application.

Conclusion

The vacuum circuit breaker production process at AIERWAY reflects precision, technology, and quality craftsmanship. From material selection to final inspection, every step is carefully managed to deliver high-performance vacuum circuit breakers that exceed global standards. With continuous innovation and customer focus, AIERWAY remains a leading manufacturer in the vacuum circuit breaker industry. Choosing an AIERWAY vacuum circuit breaker means choosing safety, efficiency, and long-term value for all your electrical distribution needs.